MAGM separator

Horizontal stratification of H2SO4 concentration between the two interfaces: AGM separator/negative plate and AGM separator/positive plate has been established. This stratification results in concentration polarization and affects VRLAB performance. An experimental method for quantitative determination of horizontal electrolyte stratification has been developed at LABD. Since the AGM separator is the media through which the ion flows and H2SO4 move, the aim of the LABD team was to modify the physico-chemical properties of AGM so as to eliminate horizontal stratification of electrolyte.

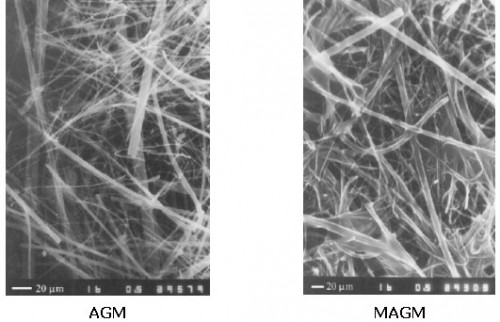

A new modified AGM (MAGM) separator for VRLA batteries, and the respective technology for its production, have been developed. The new product is obtained by processing absorptive glass mat (AGM) separator with polymer emulsion, which is adsorbed onto the surface of the glass fibres and concentrates at the sites of contact between the fibres. Thus, a continuous porous network of interconnected glass fibres is formed. The two surfaces of the AGM sheet are treated with polymer emulsion of different concentration in view of the different processes that take place at the positive and the negative plates, respectively. As a result of the above treatment the surface properties of the AGM are modified to balance hydrophobic/hydrophilic properties. Physico-chemical properties such tensile strength, H2SO4 absorption, wicking rate, chemical and thermal stability are compared for the two types of separators.

Horizontal electrolyte stratification is a result of the different processes that occur at the two types of plates as well as of the resistance that the ion flows of H2SO4 and H2O have to overcome when passing through the separator. In VRLA batteries, their movement is impeded by the AGM separator, which reduces the available capacity of the battery. The effect of the MAGM separator on the concentration of H2SO4 at the two separator interfaces during charge, discharge, open circuit and on cycling is investigated. MAGM eliminates the H2SO4 concentration differences between the two types of plates. These effects of the MAGM separator result in an increase of the available capacity of the battery on cycling and on float service, which leads to a substantial increase in VRLA battery life. MAGM improves the efficiency of the oxygen cycle and thus reduces water loss and prevents the occurrence of thermal runaway phenomena in the cells.

References

- D. Pavlov, V. Naidenov, S. Ruevski, V. Mircheva, M. Cherneva, New modified AGM separator and its influence on the performance of VRLAB, Proceedings of International Conference LABAT’02, Varna, 10-13 June 2002, p.5

- D. Pavlov, V. Naidenov, S. Ruevski, V. Mircheva and M. Cherneva, New modified AGM separator and its influence on the performance of VRLA batteries, J. Power Sources, 113 (2003) 209

- D. Pavlov, S. Ruevski, V. Naidenov, V. Mircheva, G. Petkova, M. Dimitrov, T. Rogachev, M. Cherneva-Vasileva, Valve-regulated lead-acid cells and batteries and separators used in such cells and batteries. U.S.Patent Nо: 6509118 B1, Date of Patent: Jan. 21, 2003

- D. Pavlov, B. Monahov, A. Kirchev, D. Valkovska, Thermal phenomena in VRLAB, Proceedings of the 6th International conference LABAT’2005, 13-16 June 2005, Varna, Bulgaria, p. 5

- D. Valkovska, D. Pavlov, A. Kirchev, Heat generation in VRLA battery – influence of separator type (poster), Proceedings of the 6th International conference LABAT’2005, 13-16 June 2005, Varna, Bulgaria, p. 19

- Kirchev, D. Pavlov, A. Gigova, Effect of electrolyte saturation on rate and efficiency of oxygen cycle in VRLAB, Proceedings of the 6th International conference LABAT’2005, 13-16 June 2005, Varna, Bulgaria, p. 25

PhD Thesis

V. Naidenov, A new modified AGM separator and its influence on processes that take place during operation of VRLA batteries

Keywords: horizontal electrolyte stratification in VRLAB, concentration polarization, AGM separator, MAGM separator, technology for MAGM production, hydrophobic/hydrophilic properties of AGM